Building a Beautiful City

Creating an Ideal Life

Business Section:Underground Space Development

Location:Tianjin

Project Completion Date:05,2012

Participating Mode:Design

Project Scale: Floor Area of 198,000 square meters

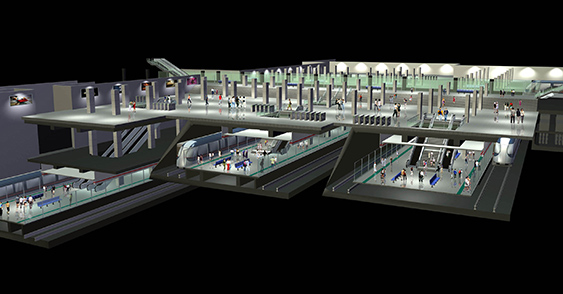

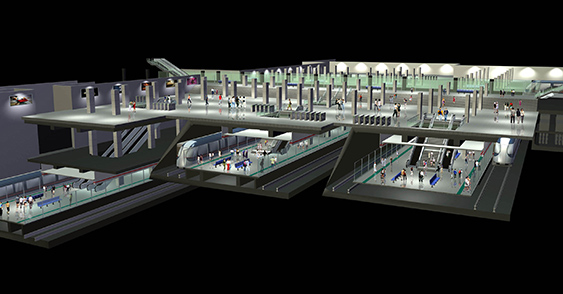

Tianjin Cultural Center is renowned for its status as the city’s guest reception hall. Its underground transportation hub is the first in Tianjin to serve as public cultural facilities, involving bus hub; parking lots; rail transport; integrated development of underground space; underground energy center and overpass tunnels. During the design stage, the hub is based on scale, network and 3D means to organize transport interchanges and passenger evacuation. The hub is designed to meet the demand of "seamless connection" of various transportation modes in the cultural center to achieve a win-win situation of underground space and to establish an underground transportation system with comprehensive functions. We first proposed the idea of reserving metro station space for renovating into an underground parking lot, to avoid the impact of a subsequent metro station construction on the nearby environment and ground traffic. It also improved the efficiency of the underground project. Based on "low carbon" and renewable energy as the guiding principle in our design concept, establishing a centralized underground energy center; using ground source heat pump + ice thermal storage assisting municipal heating network to make full use of idle power resources, so that electrical consumption at peak hours will be reduced, operating cost will be cut and environment will be improved. We also introduced a new concept with integrated natural lighting, atrium and underground space together, to balance the underground space and ground view and be environmental-friendly and energy-saving at the same time.

Business sector: Underground space

Location: Nanjing City, Jiangsu Province

Internal trial operation time: in 2022

Participation mode: Construction

Project breakthrough: The first intelligent caisson-type parking lot constructed by VSM sinking vertical shaft tunneling technology in China.

In this project, the world-leading VSM sinking shaft tunneling technology is adopted to "dig" a three-dimensional space for 200 small vehicles in a narrow area of 390 m2. On average, it takes only 1.95 m2 of ground space to park one vehicle. Citizens can gain access to their vehicles via the landscape entrance and exit on the ground. It takes them as little as 90 s to receive a high-quality parking experience. This project provides experience and reference for the intensive use of urban land resources, the development and utilization of underground space, and the expansion of effective supply of parking facilities.

The UP intelligent parking scheme proposed by STEC conforms to the development trends, such as "smart city" and “Internet +”, and fully draws on the experience and exploration on domestic and foreign solutions for parking difficulties. Public hot spots, such as downtown areas, see large flow of people and vehicles, dense layout of old buildings and tight surrounding land resources. In view of those urban difficulties, STEC creates the "three new" intelligent parking system that integrates new technology, new platform and new mode so as to solve the parking difficulty and fully activate the service efficiency of UP underground garage.

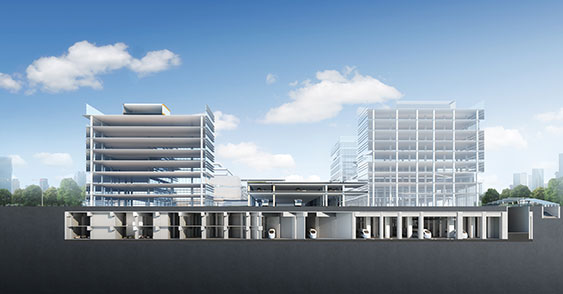

Business sector: Underground space

Location: Shanghai Municipality

Commencement time: June 2021

Participation mode: TOD mode

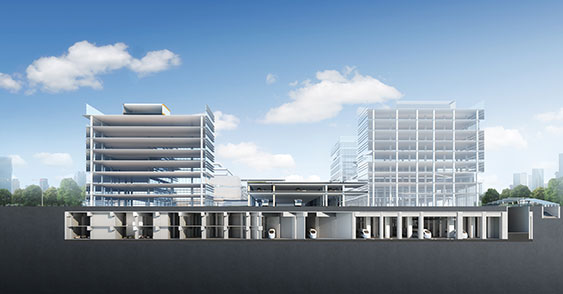

Project breakthrough: The first underground parking lot for municipal railway in China

Shenkun Road parking lot and comprehensive upper cover development project is an integrated TOD development project containing municipal railway, urban rail transit, medium volume bus, business community development and other functions. It is not only an important hub project for the comprehensive transportation development in Shanghai during the “14th Five-Year Plan” period and the "Five New Cities" comprehensive transportation system framework, but also another crucial connectivity project for the Yangtze River Delta integration and Hongqiao International Open Hub strategies.

The project is located in the core area of Shenkun Road, the "South Gate" of Shanghai Hongqiao International Open Hub, with a total construction area of over 500,000 m2. It is close to Hongqiao traffic hub in the north, adjacent to the completed Huaxiang green land in the west, and located at the intersection node between airport contact line and Jiamin Line. It serves as a crucial node for the near Shanghai area to access the municipal railway network in the future.

STEC possesses a lot of construction and management experience in the simultaneous construction and transformation of rail transit engineering and building complex, the supporting municipal engineering, the advantages of the whole industry chain, and the experience in industry resource integration. It continues to deepen the TOD project construction and management system during the construction period so as to provide reference for the construction of Shanghai rail transit complex.

Business Section:Tram

Location:Huai’an, Jiangsu Province

Project Starting Date: 03, 2014

Participating Mode:BOT

Power Supply System:Energy Storage

Project’s Breakthrough:First Tram crossing City Center in China

The project is signed between STEC and Jiangsu Huai’an government, in the Build-Operate-Transfer mode including investment, design, construction, operation and equity transfer. The total investment of Huai’an tram project is 3.445 billion yuan and the economic indicator is 172 million yuan/km for the main line. Among which a total investment of the tram project is 3.033 billion yuan and its economic indicator is 151 million yuan/km for the main line. The “BOT + Equity Transfer” investment and financing model we use allows the local government to have more flexibility in carrying out the project and balance the budget and cost. The tram, as a ‘new industry’, is also the best alternative for Huai’an government who cannot afford the huge investment in constructing metros. The first phase of Huai’an modern tram is 20.3 kilometers long, all 23 stations are above the ground, and has 4 large underground tunnels, and a depot. Huai’an tram uses a catenary-free power supply which is also the longest catenary-free power supply tramway in China. The tram uses the super capacitor which enables the vehicle to be fully charged in only 30 seconds in the station and a long life cycle of 10 years. In braking, the vehicle’s kinetic energy can be recycled into electrical energy. Huai’an modern tram connects Qinghe District, Huai’an development zone, ecological town, Huai’an District and the city’s commercial center, business center, administrative center, and culture and tourism center, becoming the first tram crossing the city center in China. It provides a reference in tramway construction for other cities, and also motivates the national transport industry towards green and energy-saving development.

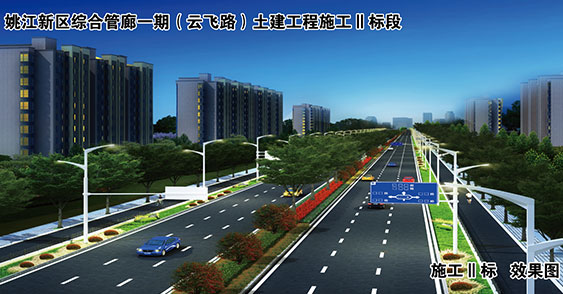

Business sector: Underground space

Location: Ningbo City, Zhejiang Province

Commencement time: April 2022

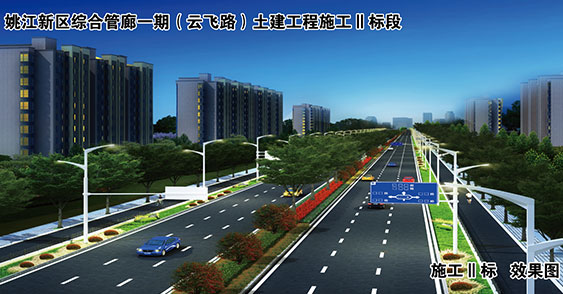

Participation mode:Engineering procurement construction

Section II (Shaodu Road - Guangyuan Avenue section) of Yunfei Road Phase II (Shaodu Road - Middle Hongtang Road) project covers a total length of 1670.56 m. The main construction comprises road engineering, operation maintenance engineering, drainage engineering, bridge engineering, etc. The section II of civil engineering construction of Yaojiang New Area Utility Tunnel Phase I (Yunfei Road) is a trunk-type comprehensive utility tunnel established under the sidewalk, the non-motor lane and the separation belt (biological retention zone) on the north side of Yunfei Road.

This project belongs to the joint construction of road and utility tunnel, which has the following difficulties. First, the excavation depth of utility tunnel foundation pit should be 5 to 10 m; the tunnel crosses 3 rivers in total so the foundation pit must be excavated with safety. Second, the waterproof grade for tunnel in this project is grade two so the main body of the project has a high waterproof requirement.

After completion, the project will drive the development in Yaojiang New Area and promote the new urbanization and the modernized urban construction in Yaojiang New Area. It will improve the comprehensive carrying capacity of urban infrastructure and facilitate the comprehensive utilization of underground space resources.

Business sector: Railway

Location: Shanghai

Commencement time: December 2021

Participation mode:Engineering procurement construction

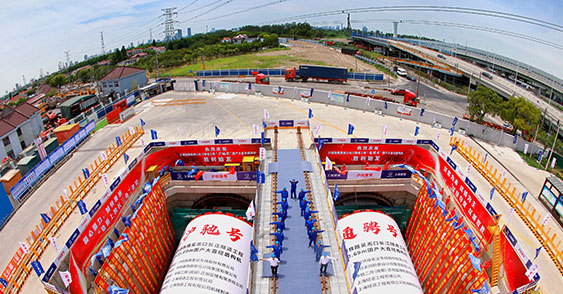

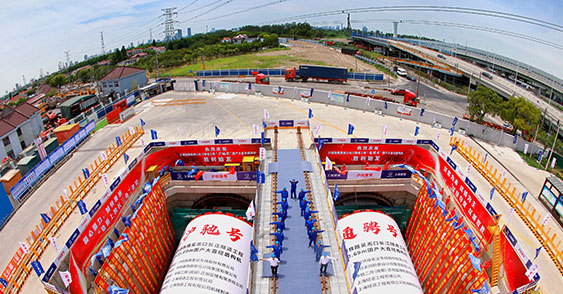

Shield tunneling machine specifications: Slurry-gas balance shield tunneling machine with a diameter of 10 m

Project breakthroughs: The first shield-type railway tunnel for both passenger and freight dug in a soft soil area in China; the first railway tunnel crossing the Yangtze River and Huangpu River in China; the first fully enclosed and lined shield tunnel in China.

Shanghai-Nantong Railway Phase II (Section from Taicang to Situan) starts from Taicang Station in the north and ends at Situan Station in the south. It passes through Taicang City under Suzhou City, Jiangsu Province, and Jiading District, Baoshan District, Pudong New Area and Fengxian District in Shanghai. The line has a total length of 111.8 km.

Among them, Wusongkou Yangtze River Tunnel (Bids HTZQⅡ-4 and HTZQⅡ-1) is the control project for Shanghai-Nantong Railway Phase II. The total mileage of the main line of the project is DK140+700 ~ DK151+485, with a total length of 10.785 km, of which the shield tunnel section is as long as 9.047 km (The section cross the Huangpu River and the Yangtze River is 4.7 km, and the land section is 4.347 km).

STEC adopts the independently developed shield tunneling machine with a large diameter of 10.690 m. It will be tested by the curve starting line, the shallow soil covering and the continuous crossing of Jiangdong Road and G1503 Belt Expressway. Next, it will directly face a series of extreme challenges posed by many buildings and structures: Penetrate under the Pudong tunnel section along the river, Binjiang Forest Park, Huangpu River Levee and Wusong Jetty; cross the international cruise terminal and the public security wharf; penetrate through the small sand back box culver, the Yangtze River Embankment and the pump station of the 14th district of Shanghai Port; penetrate under the wind channel of tunnel along the river, the Puxi open section, the overpass of tunnel along the river, the elevated Line 3 and the viaduct on Tongji Road. The minimum turning radius of shield tunneling machine is 778 m. During the long-distance excavation construction, the top priority is to maintain the micro-disturbance to surroundings.

On June 27th, 2022, the launching ceremony for "Huchi" and "Tongcheng" shield tunneling machines on the Shanghai-Nantong Railway marked that Wusongkou Yangtze River Tunnel Project for Shanghai-Nantong Railway Phase II officially entered a new chapter for shield tunneling construction.

Business sector: Subway

Location: Fuzhou City, Fujian Province

Commencement time: March 2018

Participation mode:Ordinary engineering procurement construction

Shield tunneling machine specifications: Earth pressure balance shielding machine

The first bid section of Phase I Project of Fuzhou Metro Line 4 is about 9.57 kilometers in length and located in Cangshan and Gulou Districts of Fuzhou City. It contains 8 stations, 9 intervals, 1 exit and entry line, and Hongtang depot. All of the 8 stations in this section are underground island stations, among which Jinniushan Station and Dongjiekou Station are three-storey underground stations, and the rest are two-storey underground stations. The interval tunnel has an outer diameter of 6.2 m and an internal diameter of 5.5 m. North Baima Road Station, Dongjiekou Station and Provincial Hospital Station are all constructed through full-cover reverse digging method. Fuzhou Metro Line 4 forms a part of the northeast half of the combined main urban ring of Fuzhou. The project is of great significance for Fuzhou to open the urban architecture, support the urban development, and facilitate the development in the Convention and Exhibition Center and Yixu areas.

Business sector: Rail transit

Location: Nanjing City

Commencement time: December 2016

Participation mode:Engineering procurement construction

Shield tunneling machine specifications: Earth pressure balance shielding machines with diameters of 6390 mm, 6440 mm, 6450 mm, etc.

Nanjing Metro Line 5 serves as a key line from southeast to northwest in Nanjing rail transit network and is positioned as an urban trunk line. The line covers a total length of 37.4 km and has 30 underground stations. Among them, 14 are transfer stations. The line is the "king of transfer stations". There are a total of 10 bidding sections for the whole line, of which 6 are contracted by STEC. They mainly comprise 21 stations, 22 shield sections and other ancillary structures.

Nanjing Metro Line 5 has been constructed under multiple difficulties. First, the stratum conditions are complex and changeable, with intersecting floodplain, sentry and other landforms. Sand layer, pebble layer and clay layer often interact with each other; non-layered structure is obvious, and formation pinching is everywhere. Second, there are dense surrounding buildings along the line, of which most are protective buildings, cultural relics, greening zones. They set high requirements on protection measures. Third, the shield tunneling machine passes under the two operating subway lines, penetrates through important buildings, structures, roads, bridges, rivers and other complex and high-risk areas, setting high requirements on protection measures and standards.

Business sector: Tunnel / rail transit

Location: Jiaxing City, Zhejiang Province

Commencement time: May 2020

Completion / operation time: June, 2016 for the first section and June, 2022 for the whole line.

Project breakthroughs: The first tram in Zhejiang Province.

As the first tram in Zhejiang Province, the Jiaxing Tram Project is one of the "one hundred key projects in one hundred years" and one of the ten landmark projects of Jiaxing City. It is also a major transportation facility project for Jiaxing to implement the national strategy of Yangtze River Delta integration and construct a central hub city in the core area of the Yangtze River Delta.

The Phase I project passes through 49 intersections along the way, including 27 signalized intersections and 22 non-signalized intersections. The average interval between intersections along the route is relatively close, basically 318 m to be specific. Phase I passes through 16 large and small bridges and under nearly 1 km of railways, and sees complex construction environment. The large engineering volume involves many different professional contents, such as sub-grade, bridge, track, road, drainage, greening, underground structure, housing construction, power supply, communication, operation and dispatching, geomantic electricity and escalator, intelligent building, intelligent transportation, ticket sales system, process equipment, etc.

It only took 370 days for STEC to open the first section of Jiaxing Tram. This speed has broken the conventional domestic tram construction schedule, and set a new benchmark for similar tram construction projects.

Business sector: Rail transit

Location: Shanghai Municipality

Commencement time: May 2022

Participation mode: PPP mode

The PPP project for integrated traffic hub of Wenling Station is located at the Railway New District of Wenling City, Zhejiang Province, with a total construction area of 108,800 m2. The project mainly includes four sub-projects: The east square hub, the supporting housing for rail transit, the bus transfer center and the parking building.

Facing the challenges like the wide work plane, the large volume of steel structure and the great number of buildings / structures, STEC made early plans and careful preparation. It escorted the construction of steel structure through early survey, GPS positioning, BIM simulation, advance deepening and refining of steel structure process. During the construction of deep foundation pit, STEC actively dealt with complex geological conditions, difficult support, super typhoon and other adverse factors. Thus, it ensured that the land subsidence, the maximum settlement of ramp pier and station pier column were in their controllable ranges, and guaranteed the safe operation of railway. STEC has made joint and practical efforts to construct a new traffic pattern and secured the largest and most beautiful city entrance for Wenling.

Business sector: Rail transit - urban railway

Location: Shanghai Municipality

Commencement time: June, 2019

Participation mode: Engineering procurement construction

Shield tunneling machine specifications: Slurry balance shield tunneling machine with a diameter of 14.05 m and earth pressure balance shielding machine with a diameter of 9.295 m.

Project breakthroughs: STEC adopted the 107.5-m super-deep diaphragm to dig a foundation pit as deep as 44 m, of which both are the greatest in the Shanghai rail transit field.

The airport connection line project in urban rail transit line of Shanghai Metro has a total length of 68.6 km and passes through Minhang, Xuhui and Pudong Districts, with 9 stations throughout the line. The project is scheduled to be completed for operation in 2024. At that time, the transit time between Hongqiao Airport and Pudong Airport is expected to be within 40 minutes. The airport connection line project is the first rail transit project that connects the national railway in China. As an east-west fast track connecting Hongqiao hub and Pudong hub, the project contributes to enhancing Shanghai radiation and service functions to the Yangtze River Delta. It provides strong support for Shanghai to improve its urban capacity level and core competitiveness, and to implement the national strategy of integrated development in the Yangtze River Delta. STEC undertook the construction tasks at Sections 3, 4, 5 and 12 in the airport line. They involve difficulties and highlights in ultra-low altitude construction work, super-deep diaphragm construction, ultra-long precipitation, super-large foundation pit construction, ultra-high structure construction, ultra-close crossing, internal assembly construction with fully prefabricated tunnel segments, etc.

Business Section:Underground Space Development

Location:Shanghai

Project Starting Date:12. 2011

Participating Mode:Design

Project Scale:Floor Area of 410,000 square meters

In accordance with the subsequent planning and development requirements, upon event completion, this area will be built into a municipal public activity center as a 21st century landmark, combining "premium exhibition, headquarters business, cultural exhibition, ecological habitat, tourism and leisure" together. STEC participated in the design of underground space of Central SOEs’ headquarters in Expo Park Area B, covering about 450,000 square meters. This area is located in the west side of the Expo with four major pavilions. 28 buildings in the area shall accommodate China Commercial Aircraft, Baosteel, State Grid and other 15 large central SOEs. Above the ground is a low-carbon green ecological public activity center, under the ground is a super large "underground city" complex. Area B has been built adjacent to the west of Metro Line 13 Expo Park Station. The shortest distance between the foundation pit and the metro station is only 11.9 meters, and the shortest distance with the regional tunnel is approximately 14.3 meters. The southern side Guozhan Road and Bocheng Road have a shared ditch which is only about 3 meters from the nearest sideline pit, the surrounding roads are distributed with numerous pipelines. The ditch is only 200 meters away from the Huangpu River. It is the nearest mega underground construction project in Shanghai so far. Faced with such a complicated construction environment, STEC made an overall construction plan of the foundation pit. We divided 6 pits into two parts according to the distance. We start from the far pit, and when its inner structure is completed, we adopt the interval method one after another to build the near pits to reduce the shifting and sinking impact of the construction on the metro station, so as to ensure the overall progress of the project. The construction pioneered a new model of planning, designing and constructing several buildings’ underground space together, providing valuable and replicable experience for developing underground space in Shanghai and even central China. It also offered useful insights for building a future city’s CBD.

Business Section:Rail Transport

Location:Shanghai

Project Operation Date:12, 2013

Participating Mode:Designing Contractor + Build

Project’s Breakthrough:First Single Underground Railway Tunnel with Dual Carriageway in China

The design for the station adopts the concept of “one view for one line”. We use modern building materials, technical and construction methods to build a "modern bridge” architectural image. The ancient legend "crane dances across the sand" designed for the Wild Animal Park Station highlights the special geographical and cultural characteristics of the region.

Shanghai Metro Line 16 is a regional express line, connecting Lingang and the city center. The total line is 58.8 kilometers long. We took charge of designing the entire line and part of the underground constructions. In the design of elevated section, we invented and applied the U-shaped thin-walled structure package design, construction techniques and construction technology investment decreased by about 18.5% per kilometer, compared with traditional large and small box girders. The underground section uses the single underground railway tunnel with dual carriageway in China for the first time, by presetting the wall to separate the tunnel into two semi-circular spaces. To prevent the tunnel structure from deforming, we reserved a certain gap between the top of the wall and the tunnel structure, which we called a separate structure design.

The underground section of Metro Line 16 is 10.3 kilometers long and has three underground stations. STEC constructed three intervals, two air shafts, and two stations. It is the first time a slurry shield tunneling machine of 11.58 m diameter in unstable formations was used in China. In the initial assembly of the shield machine, we use ‘frame conversion’ method to solve the problem of placing a 90-meter shield in a 49-meter-long tunnel, creating a precedent for using the large diameter slurry shield in domestic construction industry. As the key construction technology to the single underground railway tunnel with dual carriageway, the separate wall construction was attempted for the first time in China. There is no relevant construction experience to follow. We work with professional machinery manufacturers jointly developing the partition assembly robot, tunnel wall construction machines, special chassis, and other professional construction equipment. We also received national patents, and provided an example for constructing the single underground railway tunnel with dual carriageway using large-diameter shield.

Business Section:Underground Space Development

Location:Tianjin

Project Completion Date:10,2014

Participating Mode:Design

Project Scale:Floor Area of 81,000 square meters

Tianjin Yujiabao financial district is located in the core area of Tianjin Binhai New District. It’s the third major financial district in China following Shenzhen Futian and Pudong Lujiazui. B1 is a commercial street, B2 and B3 are metro line B2 and B3’s interchange area. We take charge of Tianjin Yujiabao initial Lot 9 underground space’s preliminary design, construction drawing design, the peninsula ditch, underground space design of 3.86 square kilometers, and the first phase of the shared ditch project. In the overall design of underground space, we reserved space in advance for the surrounding basements connection to ensure the sustainable development of the region. Based on the principal of developing surface and underground integration, we set rail transport as the core objective and formed a three-dimensional framework to establish an integrated commercial system, enhancing the region’s value. When designing the metro line’s entrance, we tried upgrading the design method twice to create the environment, and to improve the quality. By constructing semi-sinking platform, the atrium’s underground space is designed with full natural ventilation and lighting. After the completion of the shared ditch, the underground pipelines of the financial district can be kept centralized in the "shared ditch," and completely reversed the past situation of messy pipelines everywhere.

Business Section:Tram

Location:Zhuhai, Guangdong Province

Project Starting Date:09, 2013

Participating Mode:Design

Power Supply System:Ground-level Power Supply

Project’s Breakthrough:First Ground-level Power Supply in China

Zhuhai Modern tram is the first tramway using ground-level power supply system in China, which has zero emission during operation. The first phase project of Zhuhai modern tram line 1, designed by STEC, stretches 8.7 kilometers. All 14 stations are above the ground, and the line has one tram base. The modern trams are 100% low-floor, with steel wheel and steel rail. The whole line uses catenary-free ground-level power supply system. STEC also adopts environmental-friendly lighting system, which gradually adjust light to become brighter when the tram reaches the station, and the lighting intensity differs on holidays and working days. In addition, in order to make full use of the tram as a major public transport, STEC offers a series of value-added services for the city. That includes 10 shuttle buses’ routes and transportation plan which can serve more than 110,000 people, as the tram network is not fully developed and there are only very limited connections with existing public transports in the first phase project of Zhuhai Modern tram line 1. The first phase of the tram involve dedicated lane rights, before the traffic flow matures and early stage transportation stabilizes, some lanes will be free, while other lanes are crowded. STEC analyzed the tram lane’s characteristics, accessible time and numbers, and then set limited conditions for cars to share the tramway. That means, trams use the first-phase tramway exclusively, but at the intersections, some of the roads are shared. On the basis of intersection traffic organizing principle, STEC offered signal control strategies and intersection signal control solutions to ensure the signal control are embedded in the design. Our study on the tram is gradually expanded to more routes and functions. We also drafted guidelines to help trams become the major transport mode in the city.

Business Section:Rail Transport

Location:Nanjing, Jiangsu Province

Project Operation Date:04, 2015

Participating Mode:Managing Contractor

Project’s Breakthrough:First Single Underground Railway Tunnel with Dual Carriageway Using Large-Diameter Shield Across the Yangtze River in China

As the first national enterprise building large-scale public roads using an 11-meter shield for construction, STEC applies the large-diameter shield construction technology to rail transport, aimed to meet the clients’ need to shorten tunnel construction period and save the underground space. The tunnel, starting from East Liuzhou Rd to Shang Yuan Gate of Nanjing Metro Line 3, is 3353.94 meters long. We construct the single underground railway tunnel with dual carriageway and inner structure at the same time, with shield’s diameter reaching 11.57 meters. Because of the expansion of the shield’s diameter, the shield is able to lay two tracks at the same time. This reduces the construction costs and time significantly and saves limited urban underground space compared to traditional 6-meter-diameter shields. The metro has to go through the Yangtze River, where the geologic situation is complicated, as there are a lot of gravels, fracture zones and layers at the bottom of the river. However, due to our rich experience in previous large road tunnels, we conquered all the difficulties and successfully built a single underground railway tunnel with dual carriageway using large-diameter shield across the Yangtze River in China for the first time.

Business Section:Rail Transport Station

Location:Shanghai

Project Completion Date:2008

Participating Mode:Managing Contractor

Project Scale:Floor Area of 36,300 square meters

Shanghai Metro Century Avenue Station Project is located in Shanghai Pudong New Area, at the intersection of Century Avenue, Dongfang Road, and Zhangyang Road, with floor area of 36,300 square meters. The Century Avenue Transfer hub is an efficient integrated and resource sharing station. The height of four stations formed the shape of the Chinese character "丰". In lieu of the traditional way of transfer, a "zero transfer hub" was achieved. This innovation not only reduces transfer time and distance, but also greatly improved passengers’ transit experience. Consolidating the surrounding environment conditions during construction, we first built separately then combined all the things together. We utilized the multi-door-shaped anti-floating beam to ensure the structure stability of the station. When constructing metro line 9 station’s foundation pit, we excavated section by section and adopted a steel-concrete supporting system to prevent line 2 and 4 stations from deforming, which ensured normal operation of metro stations. The project’s technical innovations not only fulfilled the lacking part of large-scale rail transit transfer station expansion project, but also accumulated much experience in large-scale construction projects. The success of the project bears testament to our construction techniques in underground expansion reaching an international level. Our research achievements can be widely promoted in the entire underground construction industry.

Business Section:Tram

Location:Suzhou, Jiangsu Province

Project Completion Date:10, 2014

Participating Mode:Design

Power Supply System:Overhead Power Line

Project's Breakthrough:First 100% Low-Floor Tram with Steel Wheel and Steel Rail in China

Jiangsu High-Tech Zone modern tram line 1 is the first tramway in Jiangsu province, the very first 100% low-floor steel wheel and steel rail modern tramway. It is also the first tramway project to receive approval from the National Development and Reform Commission. The tram line is 25.739 km in length, and has 24 stations from Mudu at the foot of Tianping Mountain in the west to Zhongnan Street near Jinji Lake in the east. The tramline passes through 6 districts in Suzhou, with a total investment of 12.6 billion yuan. The right of way is semi-closed. Trams are 100% low-floor with steel wheel and steel rail. Overhead lines supply power to the tram. This project created a brand new situation in the development of modern trams, which also showcased STEC‘s capability as the market leader in the modern tramway industry.

Business Section:Rail Transport

Location:Shanghai

Project Operation Date:12, 2007

Participating Mode:Design & Build

Project’s Breakthrough:First Double Circle Shield Tunnel in China

A more reasonable and effective arrangement of the tunnel contour and saving the underground resources are key issues for the current city rail transport construction. We constructed tunnels from Shanghai Metro Line 8’s Huangxing Park Station to Shiguang Road Station, which is 2,688 meters long. The shield started from the Huangxing green area, passing through Xiangyin Road Station and Nenjiang Road Station, and ended in Kailu Road Station. We used the double circle shield, with a diameter of 6.52 meters and a width of 11.12 meters to complete the task. Introducing this shield for the first time helped save the underground space, limit the environmental impact and reduce the construction cost.

Relying upon STEC’s outstanding R&D team, as well as manufacturing and management capabilities in shield equipment, we had a huge breakthrough on the double circle shield construction without precedence in China. We conquered major technical difficulties like double circle shield tunnel ground deformation control, tunnel axis control and tube sheet assembly, etc. and formed a relatively complete double circle shield construction technology, laying a solid foundation for the comprehensive promotion of this shield construction method.

Business Section:Rail Transport

Location:Shanghai

Project Operation Date:12, 2007

Participating Mode:Design + Build

Project’s Breakthrough:Across Metro Line 1 under Operation by using Super-Shallow Shield

As the availability of urban underground space for development becomes lesser, planning and construction of metro line is severely constrained. Construction on Shanghai Metro Line 9’s section from Xujiahui Station to Zhaojiabang Rd. Station is a case in point. The tunnel is 1,105 meters long. Due to the space limits, the super-shallow shield has to pass over the metro line 1 without affecting its operation. The depth to the top is only 4.2-5.0 meters. In order to control the risk, and minimize the environmental impact, STEC adopted two earth pressure balanced shields, with diameter of 6.34 meters, which we designed and manufactured ourselves. Our most experienced and skilled management and construction team, successfully completed the task, through precise calculation and analysis of the tunnel’s deformation characteristics and how the super-shallow shield passes over tunnels in service, without using auxiliary measures such as foundation reinforcement which may affect the nearby environment. After calculation, the maximum settlement above the Hengshan Road is only 25 millimeters, and the maximum uplift amount of Shanghai Metro Line 1 is only 2.3 millimeters, so we have controlled the tunnel axis effectively within ± 50 mm.

Relying on our more than 20 years’ experience in rail transport construction, we are able to construct tunnel projects which are extremely difficult and high risk. We are capable of helping the city achieve the “impossible” construction dream.

Business Section:Rail Transport

Location:Shanghai

Project Operation Date:12, 2009

Participating Mode:Designing Contractor + Build

Project’s Breakthrough:Crossing 23 Heritage Buildings Continuously in Short Distance

As the shields operate under the ground in the city center, it will inevitably affect the existing buildings and equipment. STEC has enormous experiences in ‘delicate operations’ in urban centers to meet the complex environment of urban rail transit rigor requirements like construction project risk, project’s quality, civilized construction and schedule control.

Tunnel of Shanghai Metro Line 11’s Xujiahui Station to Shanghai Stadium Station is located in Xuhui core business area, which is 1600 meters long in one way, passing through 23 heritage buildings like the Xuhui Middle School, and Xujiahui Catholic Church, and metro line 1 and 4 which are already in operation. Among which, five are super-grade heritage buildings, four are first-grade, four are second-grade and nine are third-grade historical buildings. The closest distance between the shield and Xujiahui Catholic Church is only 8 meters. Through a series of land subsidence control measures, we managed to keep the soil loss rate of the super-grade heritage buildings to 1.5 ‰ ~ 3 ‰, and the overall loss rate is controlled around 5 ‰ one month after the shield passing through. We make sure the safety of the building and subway deformation is also controlled. Meanwhile, thanks to good on-site management capabilities and innovative parties construction framework, we maintained a good relationship with the residents of the surrounding communities, facilities organizations, and shopping malls, alleviating any potential problems in the central business district.

Business Section:Rail Transport

Location:Nanjing, Jiangsu Province

Project Operation Date:07, 2014

Participating Mode:Build & Transfer

Project’s Breakthrough:China’s First GPST Tunnel

STEC invested 13.45 billion yuan in constructing the first phase of the Jiangsu Nanjing Metro Line S1 Project (The Airport Line), which was carried out in the form of total integration. The airport line links Lukou International Airport in the south and Nanjing South Railway Station, which provided the most extensive coverage with the most complete investment and financing model in China.

As the earliest company to start the construction of urban rail transit system in the industry, we have professional knowledge and rich experience in rail financing, investing, designing, planning,civil engineering, mechanical electronics, operating and maintaining. During the construction of Nanjing Airport line, our professional construction team adopted several advanced construction technologies such as GPST and URUP. Guided by principles of strict quality control and construction safety, we cooperated with the best quality suppliers like China Railway Express and Hongrun, to develop a high-quality project. Thanks to our good credit resources, we incurred less financing cost to bring in Shanghai financial institutions. In order not to monopolize the local bank resources and loan amount, we extended the project financing period to 25 years, which greatly reduced the pressure on the local government to pay the money back. This also provides our client a one-stop service with the highest quality and lowest cost rail transit system.

Business Section:Rail Transport

Location:Shanghai

Project Operation Date:12, 1994

Participating Mode:Build

Project’s Breakthrough:Shanghai’s First Underground Fast Track

As the first urban rail transport construction company, STEC began the experimental project of Shanghai Metro Line 1 since 1966. In 1980, we undertook the test project of Shanghai Metro Line 1 expansion. We also completed the metro shield tunneling and tunnel lining structure selection, developed the high-precision reinforced concrete (RC) segments technology, underground diaphragm walls construction techniques, and a deep excavation technology, which were widely used in Shanghai Metro line 1 and line 2 projects later, thus reinforcing our leading position in tunnel and rail transport industries. Shanghai Metro Line 1 is a modern fast track running from north to south, across the city center. STEC constructed Line 1’s 10 stations, and 10 intervals, including Shanghai Railway Station, Caobao Rd Station, Shanghai Stadium Station, and the interval from Shanghai Stadium station to Xujiahui station, People's Square Station to Huangpi Rd Station. During the construction of Line 1, we introduced two 6.34 m diameter earth pressure balance shield manufactured by French FCB for drive-in, and also used a belt conveyor dump system for the first time.

Business Section:Rail Transport

Location:Shanghai

Project Operation Date:12, 2009

Participating Mode:Designing Contractor & Build

Project’s Breakthrough:New Design Concept of Integrating Network, Humanity, Science, and Environmental-protection into Metro Stations

Shanghai Metro Line 7 is 34.4 kilometers long. It has 28 stations, among which we constructed 9 stations, and 8 intervals. On the basis of applying advanced technology and lessons learned in domestic and abroad in urban subway construction, combining project characteristics and difficulties, we carried out autonomous innovation in overall design, construction technology, electrical and mechanical integration, energy saving, safety and environmental protection. In terms of the overall design, we suggest integrating network, humanity, science and environmental protection into metro stations, developing several metro stations and underground space together. We independently developed the new cut-and-cover method and pneumatic caisson construction technique. The subway tunnel shield construction uses the innovative micro-disturbing tunneling technology to go through service tunnel and building structures. The development and application of more than 20 scientific and technological achievements established our leading position in the rail transport industry. We also won the second prize of 2011 National Excellent Design Award, the third prize of 2006 Shanghai Outstanding Consulting Achievement Award and 2011 Shanghai Outstanding Design Award.

STEC 版权所有 沪ICP备15043468号-3

沪公网安备 31010402005457号

沪公网安备 31010402005457号