The Phase Ⅲ reconstruction and expansion project of Shanghai Songshen Water Environment Purification Co., Ltd. is located on the south of the company, the south side of Tongxin Road and the east side of Beimaojing. The construction contents involve the sewage plant and the pipeline for pump station outside the plant. The sewage plant involves the following tasks: Upgrade and reconstruct Phases I and II, and expand the capacity of Phase Ⅲ; the treatment capacity of Phase I and II is 140,000 m3/d; upgrade and reconstruct the current situation of Phases I and II, and reduce the capacity by 20,000 m3/d; the sewage treatment capacity will be expanded by 80,000 m3/d in Phase Ⅲ. After the reconstruction and expansion, the whole plant will receive new actual processing capacity of 60,000 m3/d, and its total processing capacity will be 200,000 m3/d. This will greatly improve the sewage treatment capacity in Songjiang area. The effluent quality will not be lower than Grade A standard. That is of great significance for the water source protection in the upper reaches of Huangpu River, the local ecological environment protection and the livelihood improvement.

The platform is a comprehensive urban grid management system integrating road network facility management, emergency resource management, maintenance plan management, operation monitoring management and emergency management, so as to control the operation status of road network facilities in megacities in real time and comprehensively, and greatly improve the operation and maintenance service level of urban transportation infrastructure. The platform has digitized the documentation of 1,900 km of road, bridge and tunnel infrastructure, deployed the fine management of 10-meter-level road network, managed 5000+ users, 2000+ suppliers, 2000+ professional vehicles and 200+ maintenance bases with mature big data management and decision-making mechanism, processed 5TB of data annually, received 200,000 work orders and handled 100,000 incidents. The data accumulation and management mode has been continuously iterated and optimized. The overall control of urban operation safety, operation efficiency and facility safety state has been improved, the human cost expenditure has been greatly reduced, the management resources and cost input have been optimized, and the digital transformation and high-quality development of urban operation management have been supported.

Section B in the westward route extension project of Jihua Road in Foshan is about 5.404 km in its full length. The whole route was constructed under the first-class highway standards in view of urban road functions. The project forms a part of the first-ring road westward expansion strategy of Foshan. It will become a new part of the Guangzhou-Foshan one-hour traffic circle that connects the west wing of Nanhai area, Gaoming, Sanshui with downtown area of Foshan City, and help Foshan to be better integrated into the Guangdong-Hong Kong-Macao Greater Bay Area.

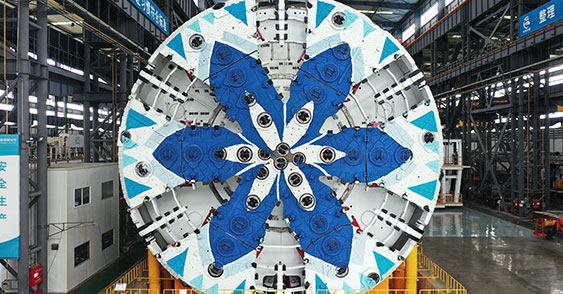

The controlled westward route extension project of Jihua Road in Foshan undertaken by STEC is a pair of single-layer shield tunnels with six lanes in two directions. The left line of shield tunnel is as long as 1,472 m and the right line is as long as 1,474.202 m. The section under river is as long as 920 m. The “Jihua No.1” shield tunneling machine employed is the first slurry balance shield tunneling machine with a super large diameter in Foshan and the largest one in Guangzhou-Foshan area. It marks an important milestone for the transport infrastructure construction in Foshan.

The project mainly includes the gasoline and natural gas (LNG) refueling unit and the hydrogen refueling and natural gas (CNG) refueling unit. The project include the principal technology of a jointly constructed station as well as the civil, electrical, automatic control, water supply and drainage, fire and other relevant public supporting facilities. The station can provide refueling services for 20 new energy vehicles simultaneously, and thus form a four-in-one three-dimensional energy services for “hydrogen refueling, LNG refueling, gasoline refueling and recharging”. The project adopts the construction mode that integrates multiple stations. In addition to its intensive land usage, it is also featured by its high efficiency, green attribute and friendliness. It explores a development path of organic integration of charging station and traditional refueling and natural gas station. The project will accelerate the development in new energy vehicle industry and strive to become an energy demonstration case that can be replicated and promoted, so as to accumulate experience for similar projects in the future.

The project succeeds in "three firsts", namely the first “primary (station) with standard (station)” project for compressed natural gas station in China, the first integrated gasoline, natural gas, hydrogen and electricity energy project in Jiangsu Province, and the first mounted (overhead) refueling project in Jiangsu Province.

Shanghai rail transit airport link line is 68.6km in length. The construction management quality and efficiency of the airport link line project can be ensured in an all-round way by the construction management platform + smart site platform. Based on the company's own BIM consulting + engineering construction information + system integration solution, the construction management platform of the project is to integrate the digital twin concept into the site safety, quality and schedule management to realize the digitalization of engineering management and the visualization of construction technology. The smart site platform is based on IOT technology to realize fine management of personnel and environment and minimize blind spots in safety management. During the implementation of the project, the company, guided by operation and maintenance, has introduced GIS+BIM engine with independent intellectual property rights, combined with UAV tilting photography, virtual reality, Internet of Things and other information technologies, comprehensively implemented BIM application technology in Shanghai railway, thereby building the municipal railway standardized industrial system, and getting through the whole life cycle data stream of "planning-design-construction-operation" of the project.

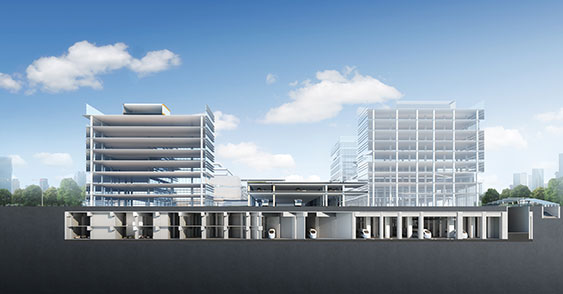

Shenkun Road parking lot and comprehensive upper cover development project is an integrated TOD development project containing municipal railway, urban rail transit, medium volume bus, business community development and other functions. It is not only an important hub project for the comprehensive transportation development in Shanghai during the “14th Five-Year Plan” period and the "Five New Cities" comprehensive transportation system framework, but also another crucial connectivity project for the Yangtze River Delta integration and Hongqiao International Open Hub strategies.

The project is located in the core area of Shenkun Road, the "South Gate" of Shanghai Hongqiao International Open Hub, with a total construction area of over 500,000 m2. It is close to Hongqiao traffic hub in the north, adjacent to the completed Huaxiang green land in the west, and located at the intersection node between airport contact line and Jiamin Line. It serves as a crucial node for the near Shanghai area to access the municipal railway network in the future.

STEC possesses a lot of construction and management experience in the simultaneous construction and transformation of rail transit engineering and building complex, the supporting municipal engineering, the advantages of the whole industry chain, and the experience in industry resource integration. It continues to deepen the TOD project construction and management system during the construction period so as to provide reference for the construction of Shanghai rail transit complex.

The phase II project of supporting utility tunnel for ethylene project in Hainan Yangpu Petrochemical Functional Zone is located in the road network area for ethylene project to the northwest of Yangpu Port. The project was designed to cover the utility tunnel works on the Yuanyi Road, Yuaner Road, Yuansi Road and Pusi Road. The utility tunnel is as long as about 7.2 km and as wide as about 6 to 9 m. It covers a total area of about 75,400 ㎡. It adopts a form of four-story steel structure truss. The project is divided into four parts. The first part extends from the intersection between Binhai Road and Yuanyi Road to the intersection of Pusi Road along the direction of Yuanyi Road; the second part extends from the intersection between Binhai Road and Yuaner Road to the Carbon 5 carbon 9 project along Yuaner Road; the third part extends from the intersection between Pusi Road and Yuansi Road to the thermal power plant along Yuansi Road; The fourth part extends from the intersection between Pusi Road and Yuanyi Road to the intersection of Yuansi Road. The project includes the utility tunnel engineering and its public grounding, the public weak current work, the video surveillance, the anti-collision facilities, and other ancillary facilities for utility tunnel.

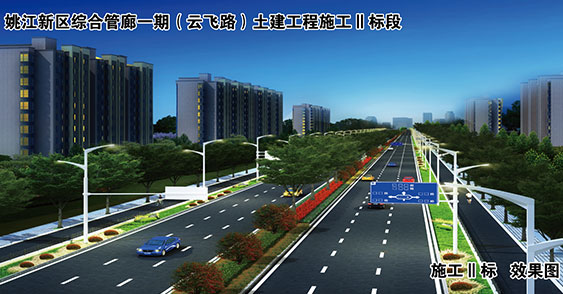

Section II (Shaodu Road - Guangyuan Avenue section) of Yunfei Road Phase II (Shaodu Road - Middle Hongtang Road) project covers a total length of 1670.56 m. The main construction comprises road engineering, operation maintenance engineering, drainage engineering, bridge engineering, etc. The section II of civil engineering construction of Yaojiang New Area Utility Tunnel Phase I (Yunfei Road) is a trunk-type comprehensive utility tunnel established under the sidewalk, the non-motor lane and the separation belt (biological retention zone) on the north side of Yunfei Road.

This project belongs to the joint construction of road and utility tunnel, which has the following difficulties. First, the excavation depth of utility tunnel foundation pit should be 5 to 10 m; the tunnel crosses 3 rivers in total so the foundation pit must be excavated with safety. Second, the waterproof grade for tunnel in this project is grade two so the main body of the project has a high waterproof requirement.

After completion, the project will drive the development in Yaojiang New Area and promote the new urbanization and the modernized urban construction in Yaojiang New Area. It will improve the comprehensive carrying capacity of urban infrastructure and facilitate the comprehensive utilization of underground space resources.

The PPP project of connection line between Hangzhou-Jinhua-Quzhou Expressway to Hangzhou-Shaoxing-Taizhou Expressway is jointly undertaken by Zhejiang Communications Investment Co., Ltd., Zhejiang Communications Engineering Co., Ltd., STEC Shanghai Infrastructure Co., LTD., and Shanghai Road and Bridge Co., Ltd. The project starts from the north side of Zhangjiafan Hub of Hangzhou-Jinhua-Quzhou Expressway and ends at Fuquan Hub of Hangzhou-Shaoxing-Taizhou Expressway. The route is as long as 22.028 km. The main construction tasks involve subgrade, bridge, culvert, tunnel, pavement, traffic safety, afforestation, etc.

The connection line of Hangzhou-Jinhua-Quzhou Expressway forms an important part of expressway network in Zhejiang Province. It is not only the main fast channel connecting Hangzhou and Shaoxing but also a key channel for Shaoxing City to integrate into Hangzhou metropolitan area and to realize the integration of three districts. Simultaneously, it is also an important link of the outer ring expressway of Keqiao District, Shaoxing City.

STEC scientifically plans and carefully organizes the construction, solves the construction and technology difficulties, addresses the bad geological section, and then get through the construction bottleneck. Based on good construction organization, STEC reasonably allocates resources and keeps balance in construction. It takes environmental protection seriously, carries out green, environmental and high standard construction, and penetrates through forest land, reservoirs and streams. STEC is committed to construct a “safe, ecological and environmentally friendly” highways and contributes to the integrated and high-quality development in the Yangtze River Delta.

It is the first component-level water facility and equipment management platform based on BIM+GIS technology, which mainly includes functional modules such as monitoring network, pipeline operation and maintenance, data analysis, hydraulic model, daily dispatching, BIM+GIS, water balance, facility and equipment management and emergency command. It can effectively identify and predict the bottleneck of urban drainage system and its possible problems and risks, and provide professional analysis and management of water pipelines, water quality, leakage, etc. Almighty hard core of refined management: The digital city twin base formed by BIM is adopted to form a visual and component-level digital asset operation and management mechanism, which provides a digital and information foundation for the integration of planning, construction and management in the field of sewage engineering in Jiaxing. Combination of virtual and real daily maintenance: Based on MR mixed reality management platform, inspection personnel can inspect through mobile terminal inspection APP, realizing the combination of "virtuality" and "reality" between BIM model of underground pipelines and inspection and maintenance site.

The river-crossing tunnel under West Jianning Road, Nanjing begins at the intersection of Xingpu Road and Jiangbei Avenue in Jiangbei New District; its main line, constructed with a bridge over Jiangbei Avenue, ends near the intersection of Jianning West Road and Rehe Road. The route has a total length of about 6,801 m, of which the tunnel section is as long as about 3,550 m (Including opening section), the subgrade section is as long as about 336 m, and the elevated section is as long as about 2,915 m. “Jianning” slurry balance shield tunneling machine with a super large diameter of 15.07 m was adopted for tunnel construction. The shield tunneling machine will penetrate through the Yangtze River levee, Nanjing Metro Line 5 and other sensitive buildings in succession. The construction of river-crossing tunnel under West Jianning Road is of great significance for Nanjing to speed up the construction of Jiangbei New District, improve the capacity of Yangtze River trunk, relieve the traffic pressure of the main city across the Yangtze River, and keeps promoting the regional road network system.

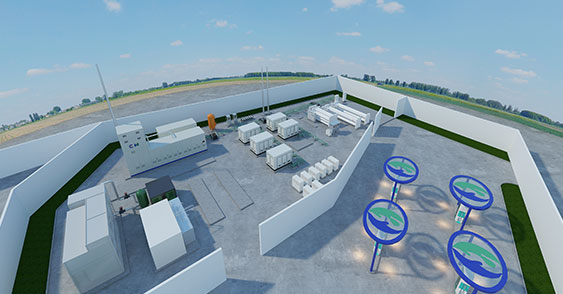

The project is located at Gaoming District, Foshan City, Guangdong Province, and covers a total area of 6, 961.8 m2. Centering on the development theme of “energy + technology towards carbon neutrality”, the project creates an integrated station for hydrogen production from natural gas and in-station hydrogen refueling. Among them, the hydrogen production module adopts the first set of skid-mounted natural gas-hydrogen production facility in China with independent intellectual property rights. It is designed to construct a comprehensive energy supply station integrating natural gas hydrogen production, photovoltaic power generation coupled with water electrolysis hydrogen production, hydrogen refueling, gas feeding and other functions.

In December 2021, the natural gas-hydrogen production facility successfully produced highly pure hydrogen, with the highest hydrogen purity up to 99.999% worldwide. In August 2022, the Phase I of the project was officially put into operation. It has filled the gap in the domestic industry and been reported with a feature story by CCTV news channel.